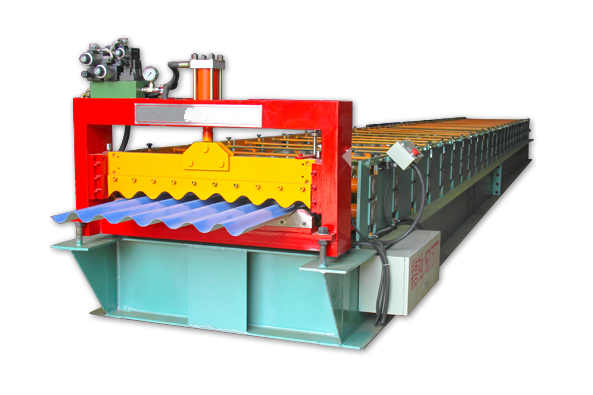

Looking for a quality and affordable Roll Forming Machine for your next project?

Hot Sale Products

All ProjectsAccessory equipment for roll forming machineColor steel glazed tile roof seriesCorrugated machineCZ purlin seriesGusset plate seriesOthersPPGI/ galvanized /Aluminum coil materialRoller shutter or car panel seriesSteel structural floor seriesThe roof&wall seriesTrack and stud keel machine seriesWater tube and gutter channel series

The feature of Botou roll forming machine

Roll Form Group Botou Company is a factory which is the first and the only one produce hydraulic roll forming machines in Botou City. Our hydraulic machine especially c purlin machines are with high reputation from our clients. 1.Our machine with high speed, normally our corrugated and Ibr roofing sheet roll forming machine can reach 25m/min, and glazed tile machine can reach 5m/min. 2. Our machine with low noise. 3. With beauty appearance and easy operate. 4. 2 years warranty for machines, and whole life to repair. 5. Energy-saving power. Hydraulic system only needs one motor, which will save more power than common two motors electrical machine.